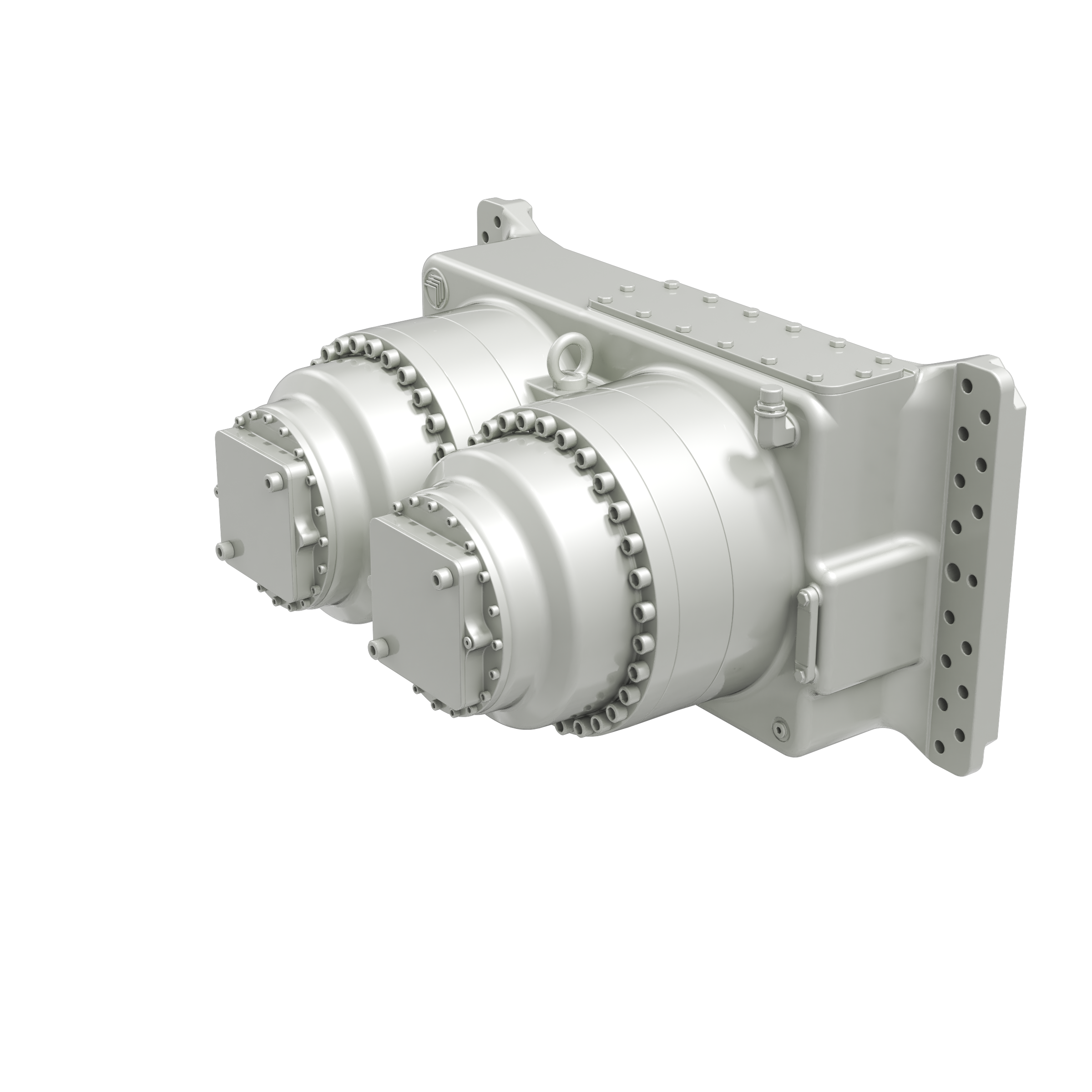

R3 Series

The R3 Series is compact and powerful. Their planetary gear train makes them the ideal choice for all heavy-duty applications where shock loads and impacts are more the rule than the exception. The product configuration is highly flexible, thanks to several mounting, synchro gear layout, output shaft and motor interface options. According to the torque need and customer machine layout, the R3 Series can be equipped with 1, 2 or 4 hydraulic motor adapters; an electric motor adapter is also available upon request.

key features

compactness

torque density & high shock load capability

I/O interface customization

Specifications

Stall Torque Range

Graphic description

| Type | Torque (Nm) |

|---|---|

| R3 16 | 129000 |

| R3 17 | 180000 |

| R3 18 | 250000 |

| R3 19 | 370000 |

Max radial force

From 56 to 117

Applicable motors

• Piston hydraulic motors

• Electric motors

• Electric motors

Specifications

Key benefits

easy integration & maintenance, cost effective, reliable drive solution

Main options

• Synchro gears

• Plug in output flange, or shamrock shaped pinion for up to C5 surface protection (ISO)

• Plug in output flange, or shamrock shaped pinion for up to C5 surface protection (ISO)

Output

• Shamrock solid output

• Output shaft: splined

• Output shaft: splined

Input

• Input adapters suitable for Axial piston hydraulic motors

• Electric motor adapter (IEC, NEMA or customized)

• Electric motor adapter (IEC, NEMA or customized)

Products and solutions request