Optimise water and wastewater processes through the correct power transmission

Markets

Solutions

Search on site

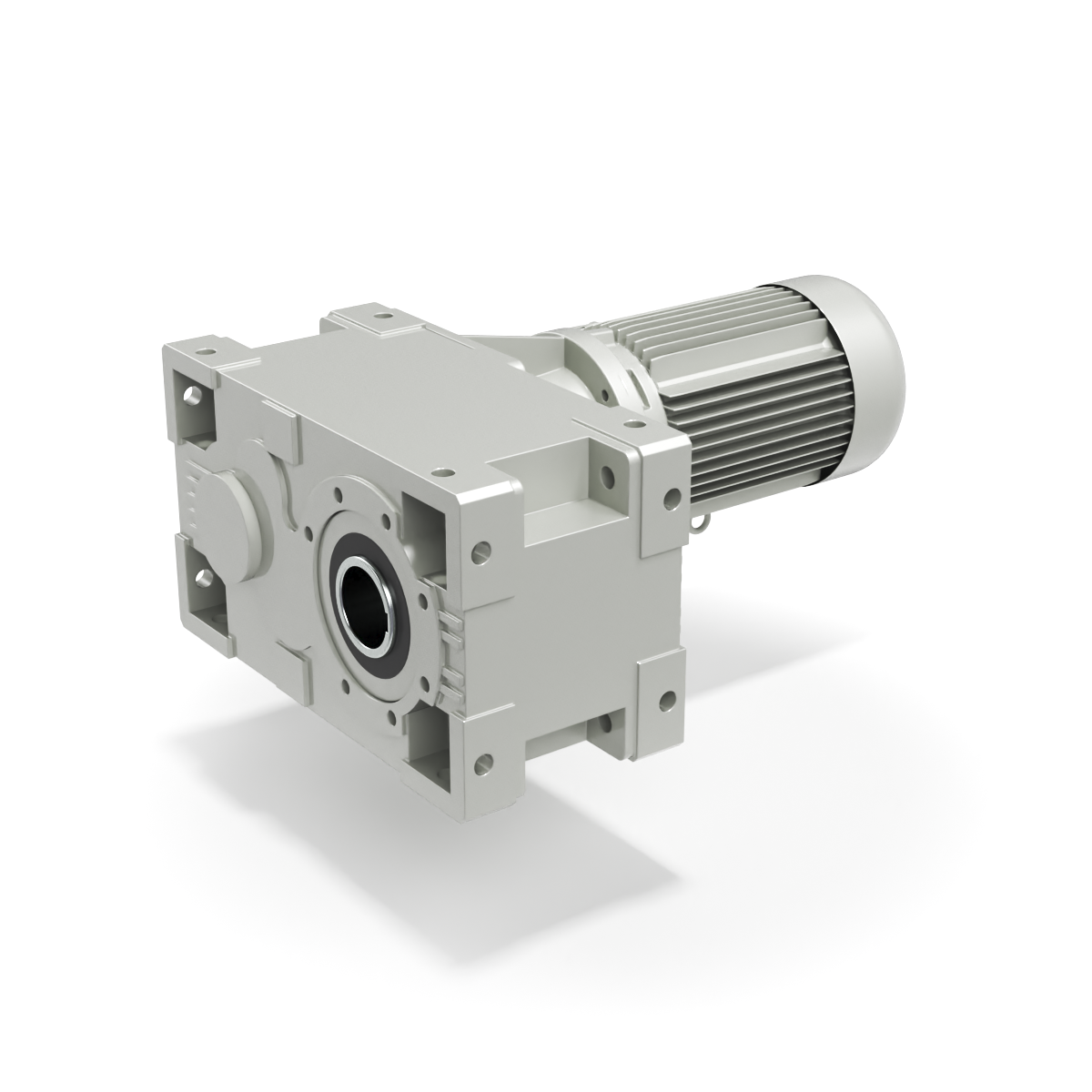

In industrial water and wastewater treatment applications, efficient power transmission technology is critical in ensuring optimal control of water flow and pressure. This facilitates the effective management of scarce water resources as well as effluents and sludge.

“Customers in plants, mines and other Australian industries are increasingly seeking out gearmotors that not only deliver on effective performance, but also bolster productivity and energy efficiency, while reducing operating costs,” comments Alan Young, Manager for Bonfiglioli Queensland & N.T

Energy efficiency is essential

Globally, plants are under immense pressure to reduce energy consumption, in line with the United Nation’s sustainable development goals (SDGs) and to satisfy environmental, social and governance (ESG) criteria.

“Certainly, mining companies and manufacturing plants are under significant pressure to demonstrate a commitment to combatting climate change, and to adopt more sustainable operations, in order to retain investors and operating licences,” comments Alan. “The good news is that gearmotor technology has advanced substantially, with modern equipment offering energy efficient operation, without compromising on power or torque range.”

Enabling automation

The automation of water and wastewater treatment processes has been identified as a means to achieve multiple benefits, among these are reduced labour requirements (and costs), enhanced efficiency, data-driven operations and improved maintenance.

“Our ongoing investment in innovation has yielded solutions that enable the automation of power transmission systems. Our easy-to-use human machine interfaces (HMIs) are easily integrated into existing plant operations, giving plant owners and operators greater control and improved visibility,” notes Alan.

Optimising plant space

The optimisation of a plant or mining footprint is a challenge for companies seeking to maximise productivity - without incurring the costs associated with expansion. This is driving demand for equipment that is compact, easily installed and offers flexible configuration.

“Our portfolio of gearmotors for water and wastewater treatment applications is modular and customisable, enabling space saving,” says Alan. “This, in turn, means that our solutions can be quickly and easily adapted to any changes in the water treatment requirements, such as changes in flow rates or pressure”.