Biogas is among the sustainable energy sources incentivised by the Green Deal policy package that Europe hopes will help it become climate-neutral by 2050.

Biogas operators tend to specialise in processing either agricultural waste, with plants located within or near farms, or urban waste gathered through recycling channels, with plants located near cities.

Bonfiglioli’s solutions are especially effective for operators that prioritise return on investment through a lower cost of operation and as little downtime as possible.

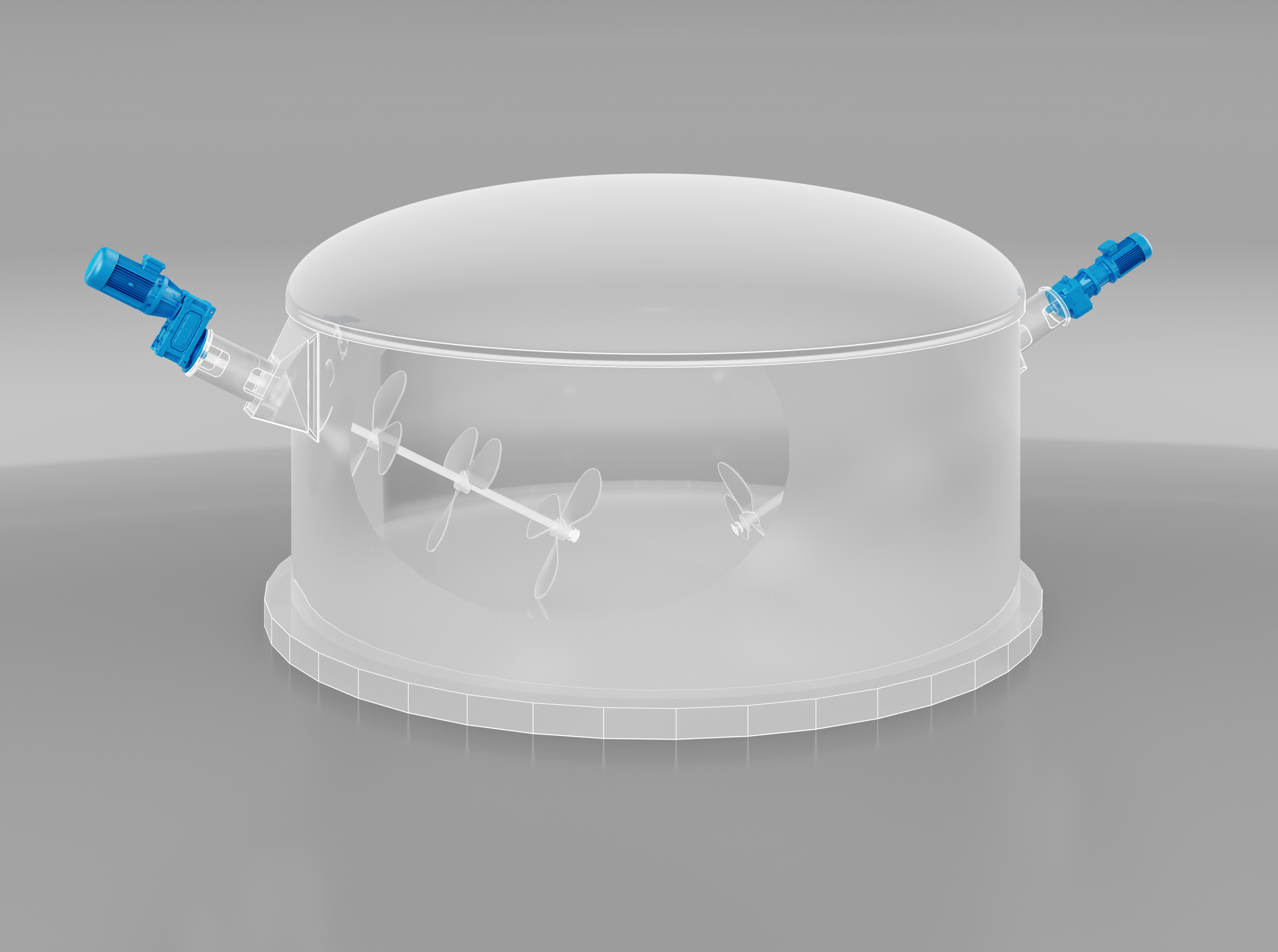

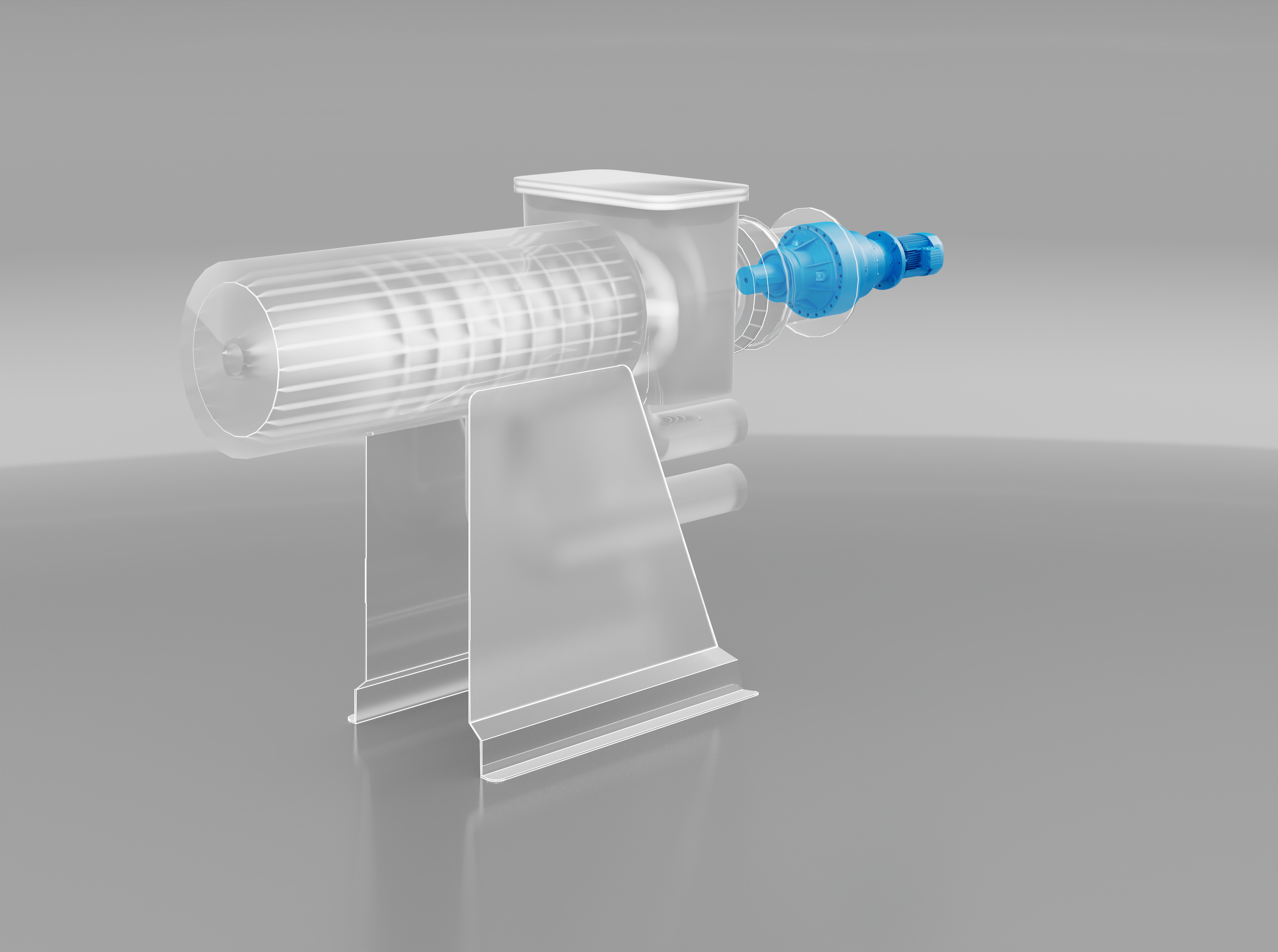

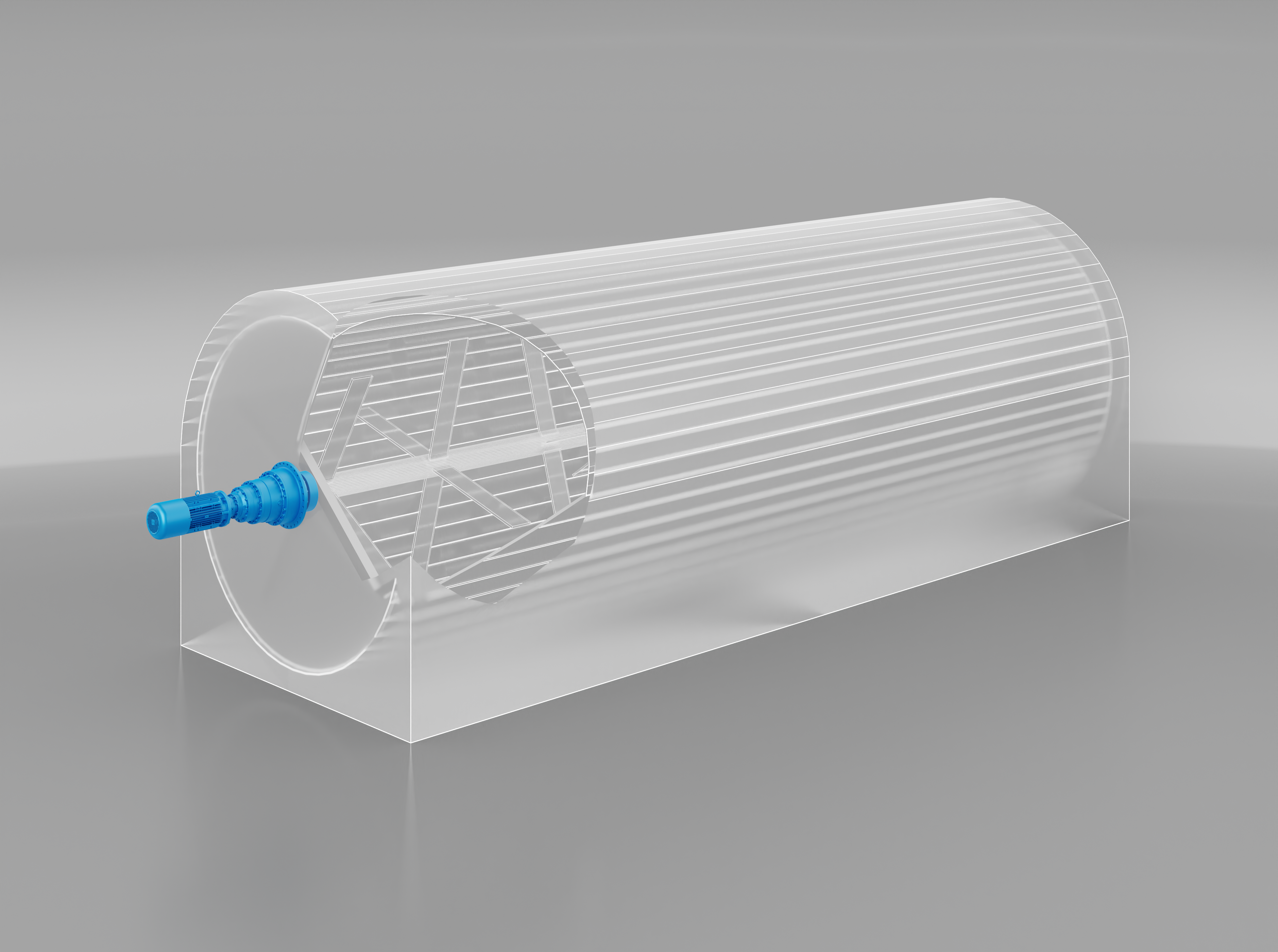

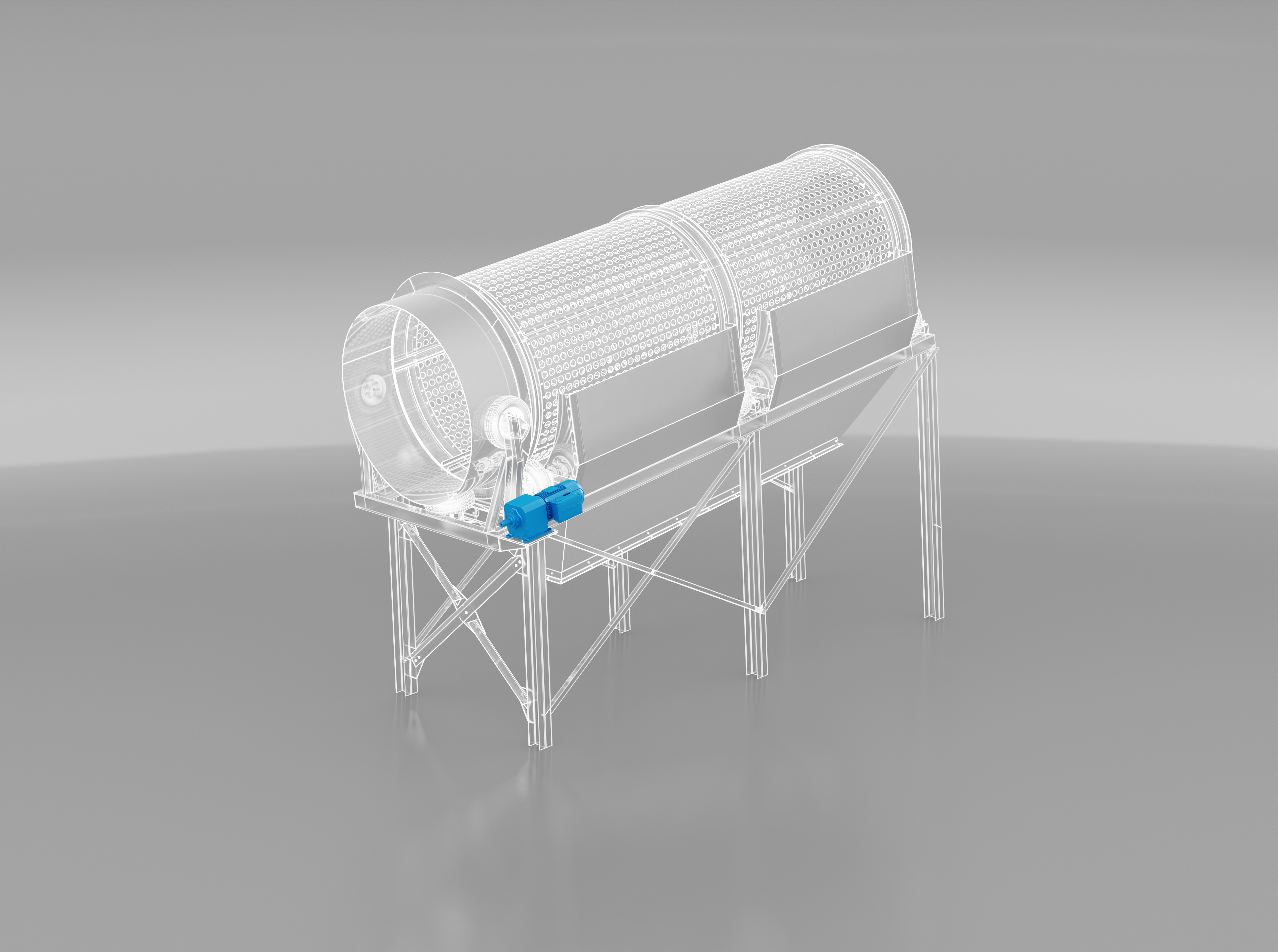

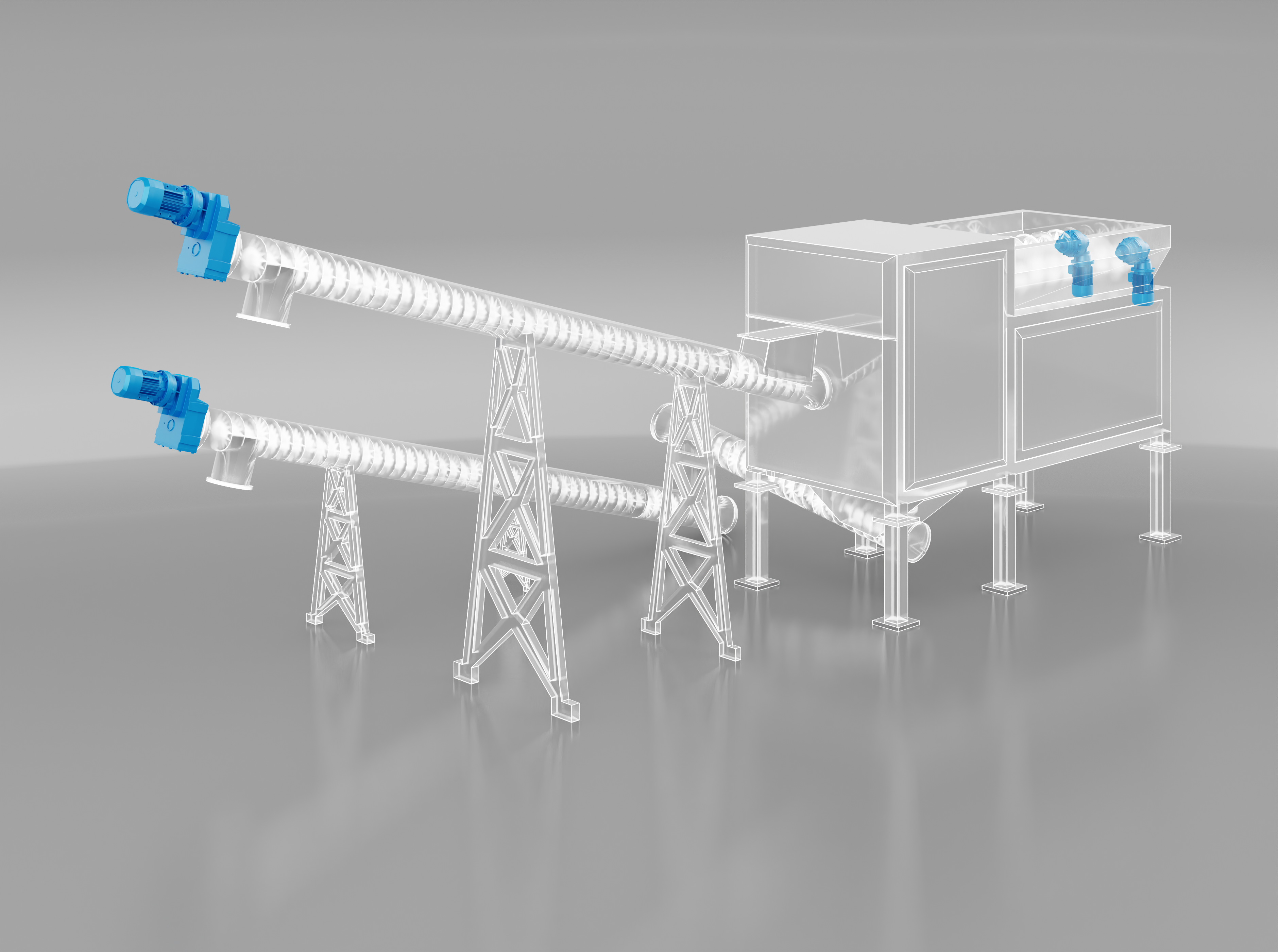

For example, our gearmotors can handle material mixing at variable power and speed ratios, threshing and transport of both solid and grain material. Their reliability and durability is already trusted by German machinery companies, which uses them in the agitators it supplies for biogas mixing tanks.