Welcome to The World of Larger Drives

IIoT Solutions

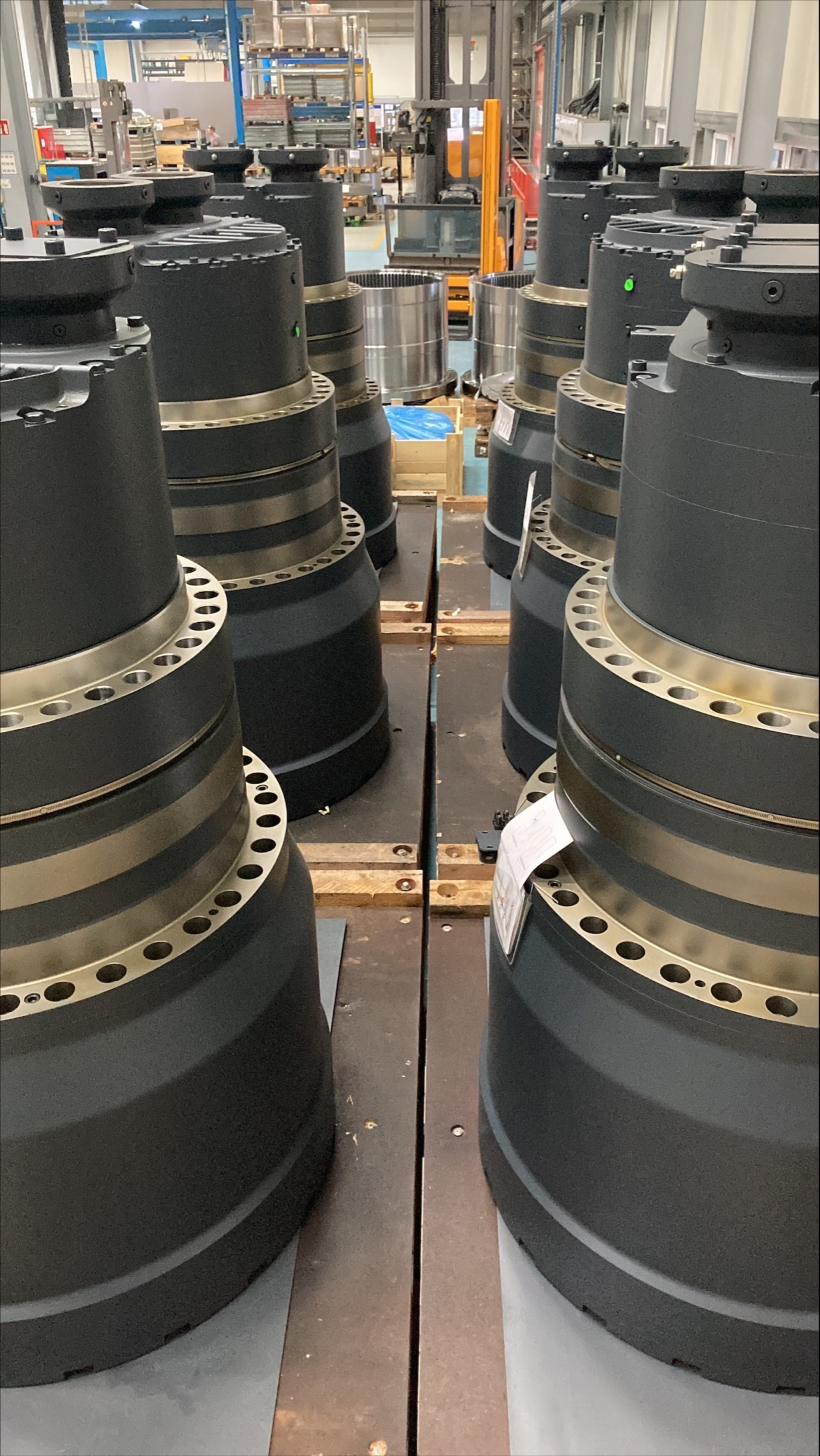

Welcome to O&K Antriebstechnik GmbH, the leading German brand in the heavy-duty and high-performance power transmission sector. This company was founded in 1876 in Berlin, and became part of our group at the end of 2015. It boasts a complete range of planetary drives, including final drives, slew drives, travel drives, winch drives, cutter drives and TBM drives. O&K gearboxes stand out with their compact and robust design, achieved by using high quality taper roller bearings, forged steel and ground gears.

As part of the Mobility and Wind business unit in the Bonfiglioli Group, O&K produces customized gearbox solutions for three key markets: mining, construction and marine. The huge O&K range of applications include Crawler Cranes and Excavators, Soil Compactors and Milling, Road Headers, Drilling Rigs, AG Harvesters, Tractors and Sprayers, Tunnel Boring Machinery, Winches and Offshore. Today, O&K is recognized for its solid expertise, the capacity to adapt the design of its products according to customers’ requirements, and its high technological development standards.

The construction and mining sectors have been outstanding in the last few years. As a famed and well-established manufacturer of complete machines for the mining sector, especially excavators, O&K has a deep and comprehensive knowledge of the uniqueness of these applications. The demand for large and extra-large (F360 – F2200) gearboxes for applications like large excavators or crawler cranes have been highly significant in the last years and is continuing to be important. O&K has long been a reliable and consistent gearbox manufacturer for mining excavators from 100 tons upwards.

A brand new development is the F420 gearbox, which is completely redesigned and optimized for customer requirements. The 714T Bonfiglioli Trasmital Slew Drive completes the supply of this 200 ton machine. Thanks to its synergies with the Bonfiglioli Group, O&K is able to extend its supply possibilities by leveraging Bonfiglioli’s mass production. As market needs are constantly growing and total cost of ownership becomes more relevant, Bonfiglioli O&K develops solutions to satisfy the needs of our customers.

This is why we are developing an innovative IIoT Solutions to monitor the relevant performance data of our gearboxes, including load distribution, vibration, oil quality and residual lifetime. All the data can be visualized on a special dashboard that enables quick analysis and profound interpretation of the generated data. As part of predictive maintenance, this enables us to provide targeted and application-specific recommended actions in order to reduce the downtime of the machinery and to guarantee the longest possible gearbox lifetime. The R&D department is investing extensively in engineering, and optimizing special customized solutions for various applications.

The German plant has also been equipped, with a dedicated team, to supply a 360° Lifecycle Service starting from Technical support, Service workshop, and Reengineering activity for complete gearboxes.

Moreover, a Remanufacturing and Retrofitting service kit strategy for exchangeable components has been designed, to maintain the full functionality of the existing gearboxes in the field. In particular, the fast-growing mining market offers O&K an excellent opportunity for growth.

We have therefore developed new gearbox solutions in the F280-F360 range, tailored for applications like surface miners and coal mining machines, which are widely used in the market. These optimized gearboxes are characterized above all by their high robustness in harsh application conditions.

Winch applications in the marine sector are another point of interest for Bonfiglioli O&K. Considering the positive global trend in demand for offshore wind turbines, the quantity of the vessels required will also increase significantly.

Consequently, we are redesigning our complete FW-series in order to offer the most compact gearbox design which enables customers to reduce several relevant cost factors, for instance by downsizing their gearbox drums. Our latest development is the FW560 gearbox, which is used in large offshore cranes.

This new gearbox type complies with all relevant classifications and meets all the marine industry’s requirements. We wish to underline our close partnership with our customers, who continuously supply us with constructive feedback regarding their market, and our products’ performance in their applications.

These outstanding relationships, characterized by mutual trust and the commitment to each other, motivate us to continue our pioneering role in gearbox technology.