Markets

Solutions

Search on site

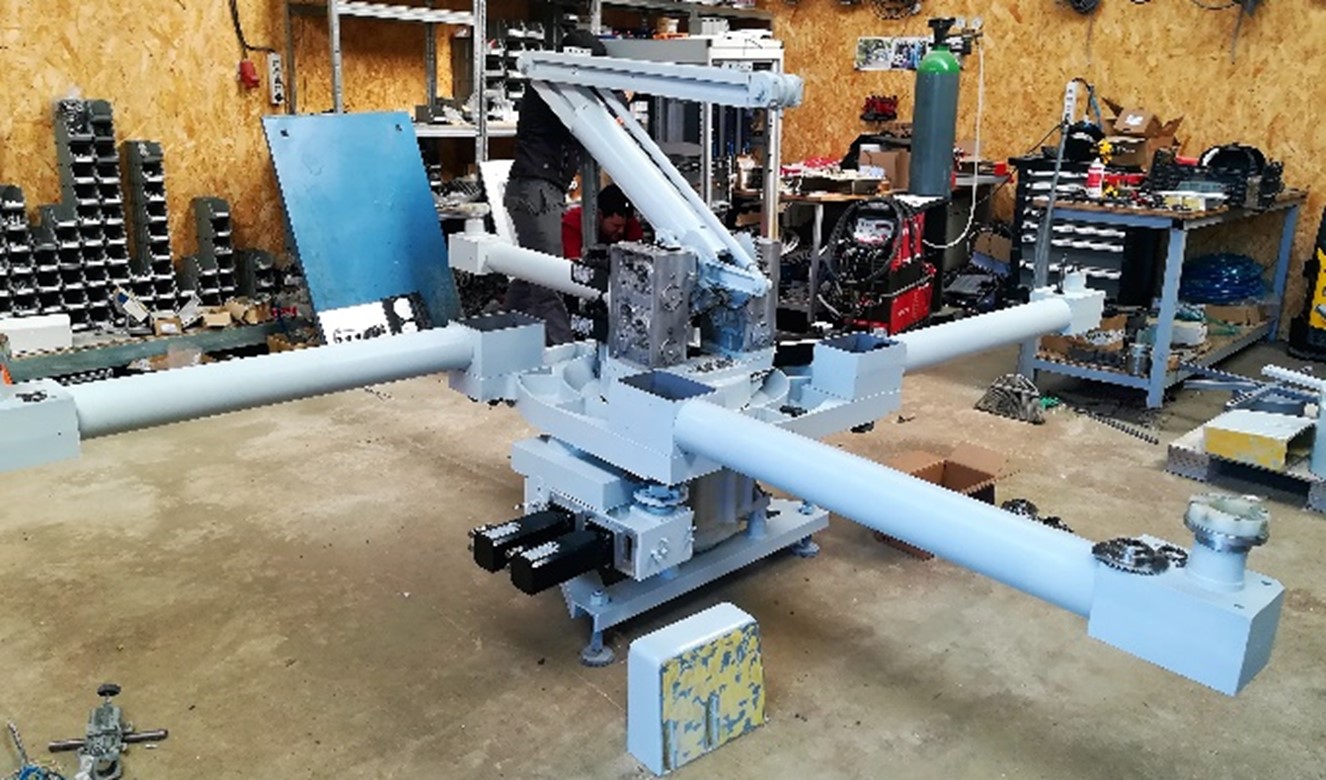

We present the solution designed by Bonfiglioli for an automatic painting robot, a customised application that provides a specific answer to the requirements of this company.

Our customer PRM is a systems integrator providing engineering services at a wood furniture company. This customer has some outdated and malfunctioning paint robots. Bonfiglioli, together with PRM, developed a solution to upgrade these robots using a customised solution for this application with Motion controller system.

The robots originally had DC motors and special controller with no fault or error diagnostic interface and no production rate monitoring.

Tecnotrans Bonfiglioli accepted this project taking into account the previous situation and the circumstances it was faced with when starting the design of this application. In the first place, one of the situations that had to be faced was that there were no certificates of the machine, and therefore, its operation had to be empirically verified.

Another challenge we faced was to design and adapt the solution to the existing mechanics, a problem that we worked on and solved, finding the exact solution required by the application. One of the key points is that the entire development was carried out remotely using augmented reality technologies.

The previous robot with no fault or error diagnostic interface and no production rate monitoring

For this customer, Tecnotrans Bonfiglioli developed a customised and tailored solution with advanced technology and production monitoring interface. The components used for this solution, developed together with the PRM integrator are:

- 7-axis servomotor system.

- Standard products.

- HDMI fault monitoring function.

- Monitoring of the production index.

- Remote assistance.

- IIOT.