Bonfiglioli’s solutions are developed with the highest level of customization. Right from the initial design phases, we work close to our customers to create a product that perfectly meets their expectations and solve their issues. Discover more about a special solution that we designed for Arjes, one of the world’s leading shredder suppliers.

Bonfiglioli conceives, designs and produces custom solutions for processing, shredding and sorting of waste materials. All solutions are developed with the highest level of customization, which requires, right from the initial design phases, in-depth interaction between the customer and Bonfiglioli’s team, to ensure that all the required specifications and variants are known, to obtain a product that perfectly meets the expectations.

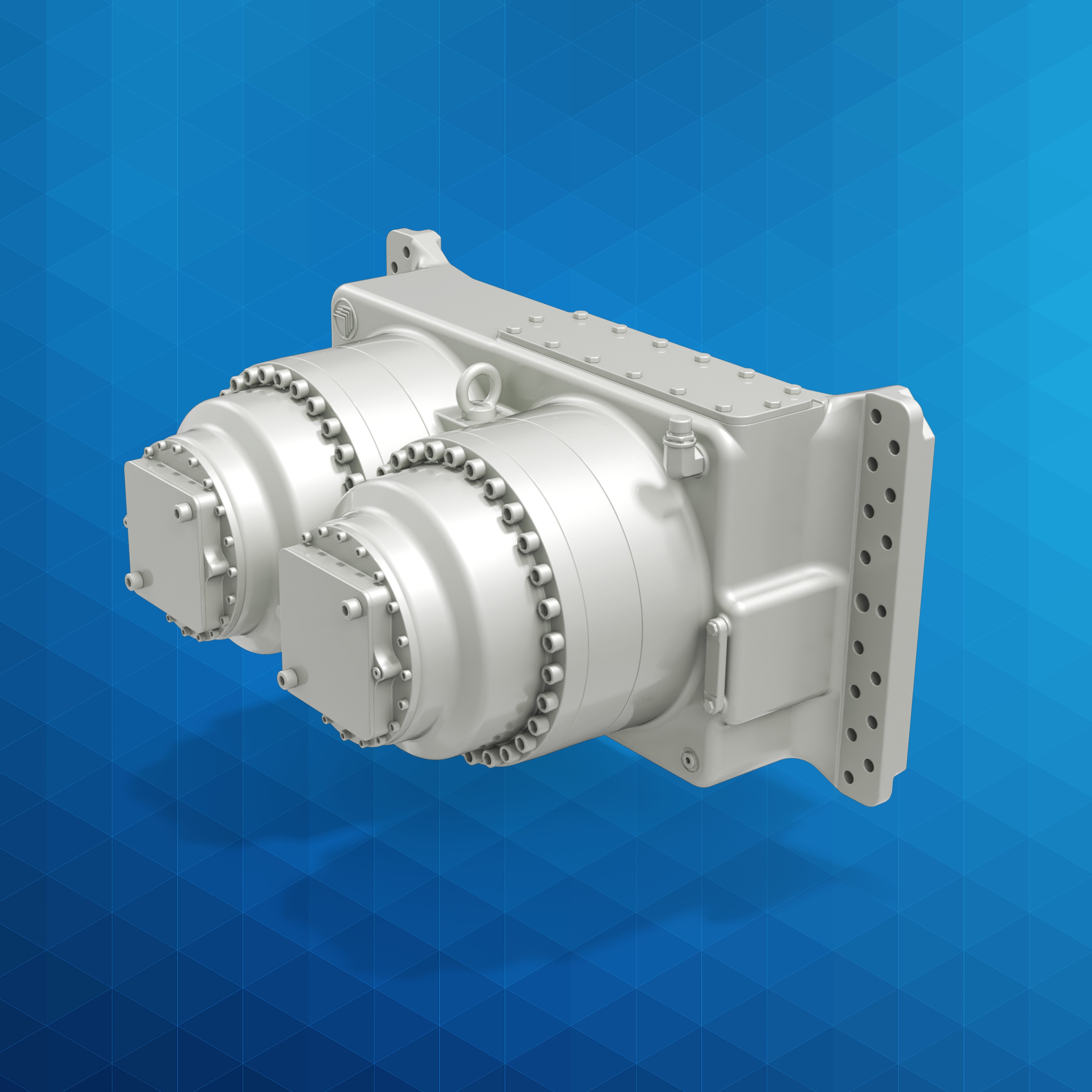

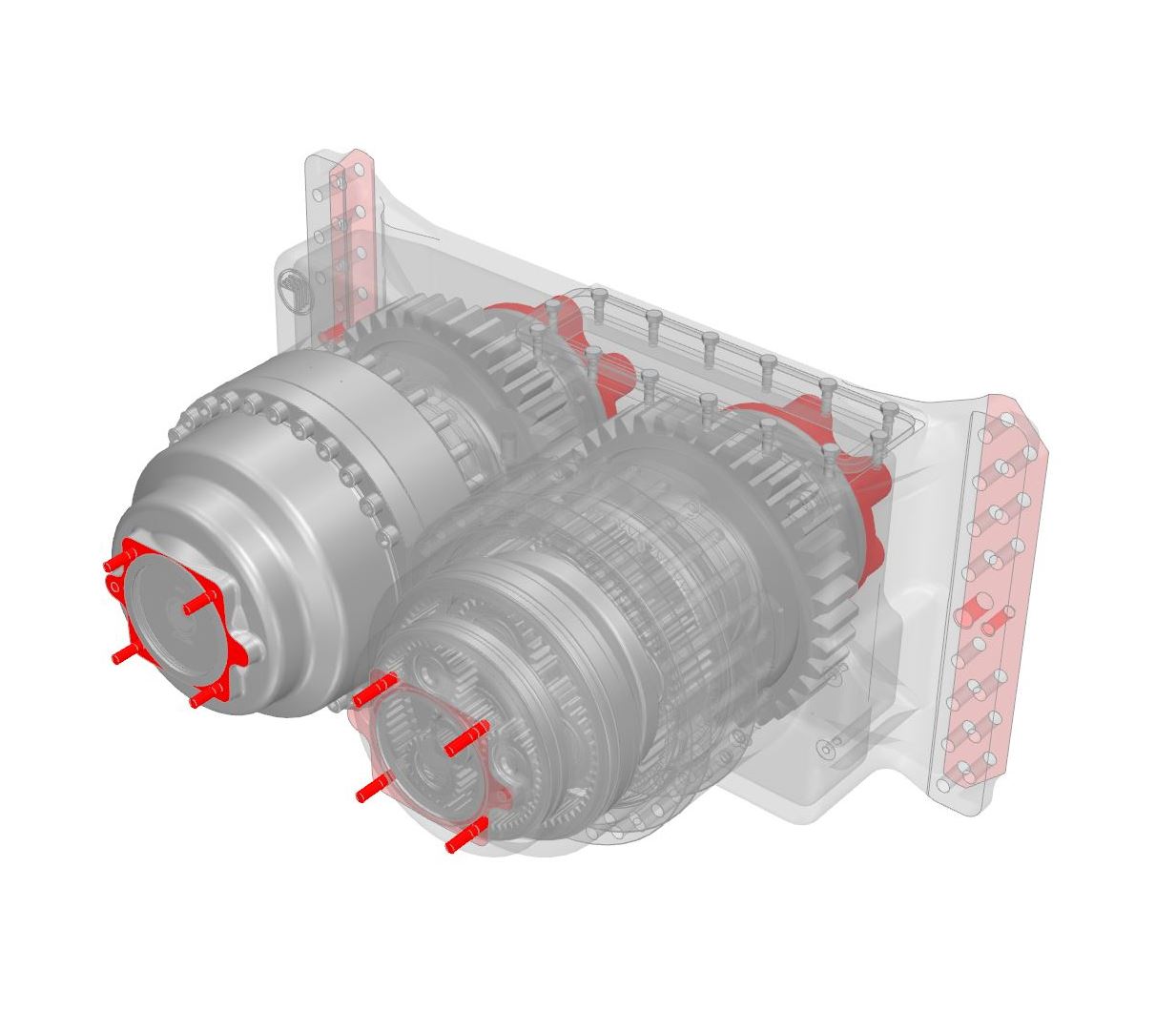

The result of this co-engineering project was a gearbox for Arjes pre-shredder Impactor 250 EVO. In addition to the combination of track mobility and hook lift version, the IMPAKTOR 250 EVO is characterized by a revolutionary quick-change shaft system, an innovative control system and a shaft design that expands the range of applications of the shredder many times over.

While developing a gearbox for the customer pre-shredder Impaktor, we faced many challenges:

To meet our customer’s needs, we developed a new modular planetary gearbox starting from our renewed 300 Series. Indeed, the 300 Series has been further extended and enriched with the new R3 Series that boasts design features allowing higher productivity and reliability for recycling applications.

Many technical improvements have been made to meet the specific requirements of the recycling sector. Bonfiglioli’s R3 planetary gear Series fulfils the requirements and operating conditions of a wide range of shredder applications.

Due to their compact design and different motor adapters available for hydraulic motors, Bonfiglioli planetary gearboxes guarantee the highest torque and efficiency for processing various types of waste.

The most important design features of the R3 Series are:

The following application data was implemented on this special case:

Bonfiglioli Headquarters

Via Giovanni XXIII, 7/A

40012 Lippo di Calderara di Reno - Bologna (IT)