Manufacturing

-

-

-

Industry 4.0

Our plants’interconnectivity lets us increase production capacity through precise monitoring of our global operations.

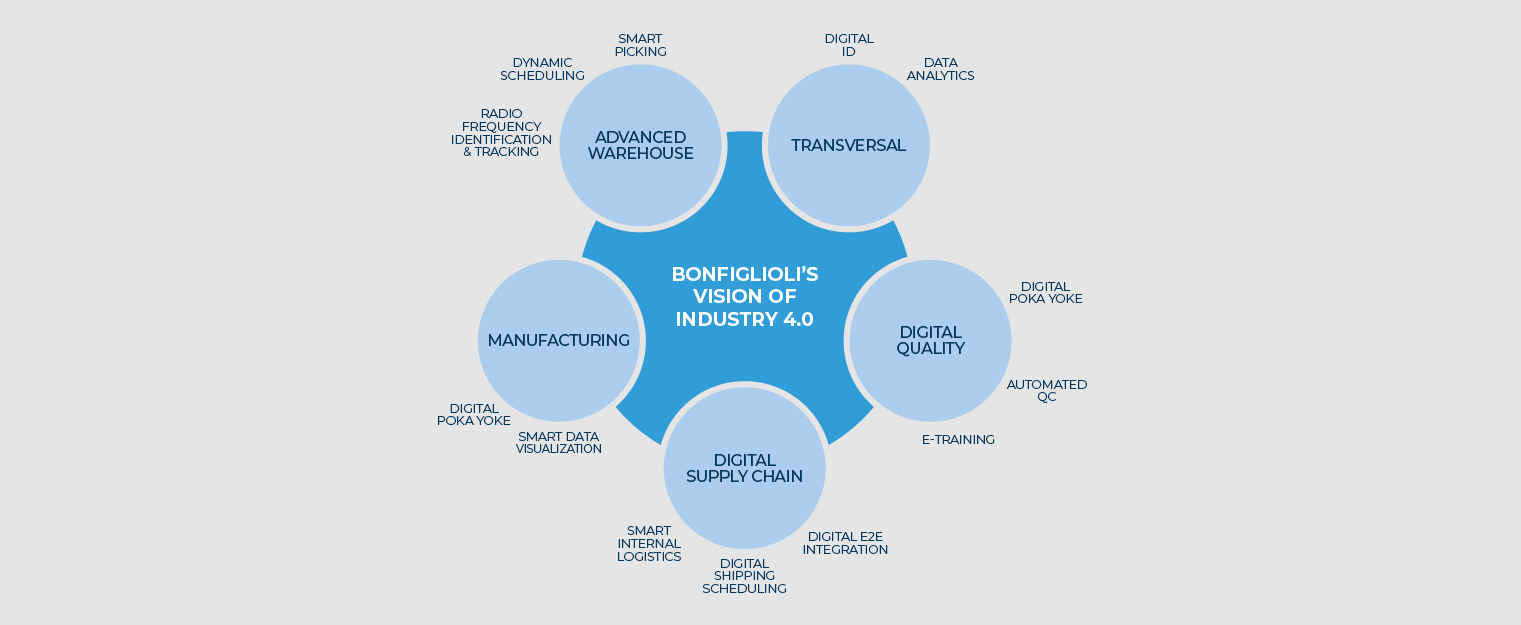

Bonfiglioli’s Industry 4.0 vision

Industry 4.0 enables much quicker flow of customized products and can radically reduce inventories throughout the supply chain reducing our customers’ machines time-to-market.