ANG Series

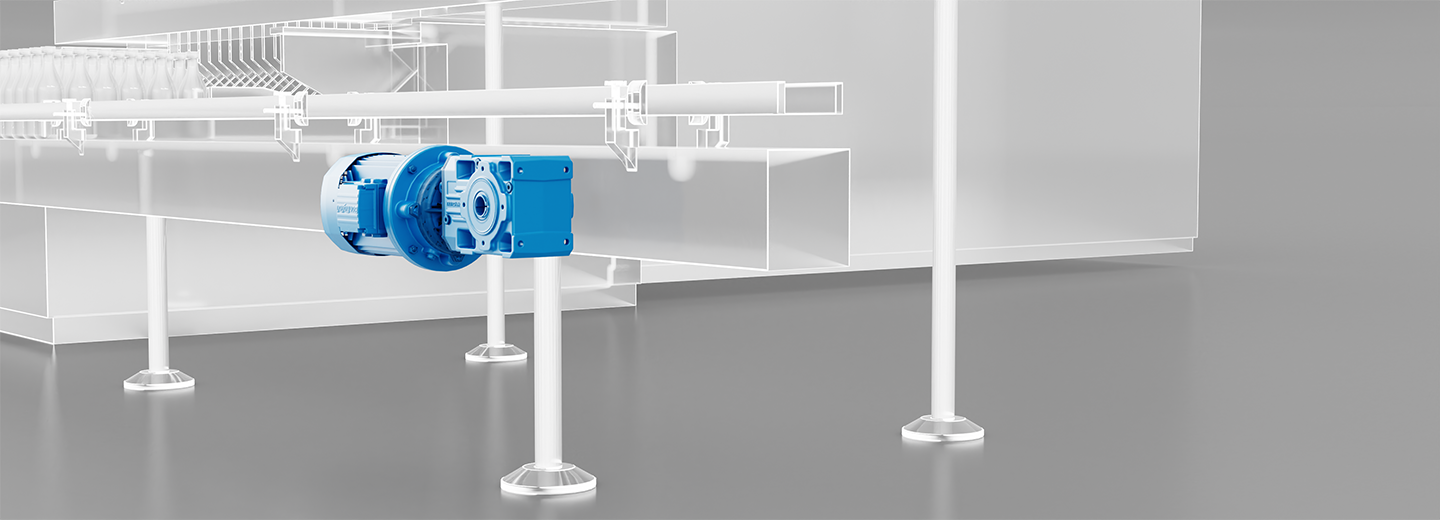

The servo inverter series ANG Active Next Generation, has been designed to provide machine builders with high performance. The new integrated micro controller allows enhancement of new functionalities such as cyclic synchronous positioning mode with cubic interpolation, brake control, and evaluation of feedback contact. This solution has been developed to meet the specific requirements of special machinery in a broad range of industries. With this new servo inverter series, Bonfiglioli offers the broadest connectivity with the most advanced control technology and the highest power density.

key features

Different variants include field bus connection and encoder evaluation

Plug-in and programmable control terminals

Plug-in power terminals (up to 3kW)

DC link connection

Integrated brake chopper

Positioning function via field bus (Motion Control compatible to CiA DS402)

Cubic Interpolation

Integrated VPLC

Master/slave function with electronic gear

Power failure control

Integrated safe torque off STO (SIL 3 / PL e) function

Output frequency 0...599 Hz, higher frequencies on request

Diagnosis and setup via optional keypad or PC software

Specifications

Degree of protection

IP20 (EN 60529)

Certifications

UL508c

STO (EN13849 / EN 61508)

STO (EN13849 / EN 61508)

Output

0 ... 599 Hz

Specifications

Main options

Optional Keypad for easy setup, commissioning, parameterization, copy function and diagnosis

Optional Interface for communication to PC

Variants

Variants Automation Interface:

• EM-AUT-01: EtherCAT® and Encoder evaluation (TTL, HTL, Resolver,

Hiperface, EnDat 2.1)

• EM-AUT-04: EtherCAT®

• EM-AUT-11: PROFINET and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

• EM-AUT-21: Ethernet/IP and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

• EM-AUT-31: Varan and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

Options

• Optional Keypad for diagnosis and parameter setup

• Optional PC Interface

• Optional accessories like brake resistor, mains chokes, mains filters

- KP500: Removable keypad

- KPCMK: Cabinet mounting kit and handheld for keypad

Optional Interface for communication to PC

- KP232: Serial communication interface, which can be mounted & unmounted during operation, recommended for service personnel

- ISO-USB: USB to Serial adapter, galvanic decoupled

Variants

Variants Automation Interface:

• EM-AUT-01: EtherCAT® and Encoder evaluation (TTL, HTL, Resolver,

Hiperface, EnDat 2.1)

• EM-AUT-04: EtherCAT®

• EM-AUT-11: PROFINET and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

• EM-AUT-21: Ethernet/IP and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

• EM-AUT-31: Varan and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

Options

• Optional Keypad for diagnosis and parameter setup

• Optional PC Interface

• Optional accessories like brake resistor, mains chokes, mains filters

Power supply & Power range

ANG410: 0.25 - 400 kW / three-phase 360 - 480V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

ANG210: 0.25 - 9.2 kW / single or three-phase 200 - 240V / 50 - 60 Hz (± 10%)

ANG510:160 - 400 kW / three-phase 525V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

ANG610: 160 - 400 kW / three-phase 690V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

Control of asynchronous and synchronous motors.

Control methods:

EMC filter integrated up to 9.2 kW (EN61800-3)

Parallel connection up to 1200 kW

ANG210: 0.25 - 9.2 kW / single or three-phase 200 - 240V / 50 - 60 Hz (± 10%)

ANG510:160 - 400 kW / three-phase 525V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

ANG610: 160 - 400 kW / three-phase 690V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

Control of asynchronous and synchronous motors.

Control methods:

- V/f

- Field-oriented control with encoder

- Field-oriented control without encoder

- 100 % continuous output

- up to 150 % for 60 s

- up to 200 % for 1 s

EMC filter integrated up to 9.2 kW (EN61800-3)

Hardware features

Integrated safe torque off (STO SIL 3 / PL e) function

- External 24Vdc supply

- Integrated dynamic braking module

- DC link connection

- Various feedback sensors

- Encoder interface for Resolver

- Cubic interpolation

- Motor temperature monitoring

- Plug-in power terminals (up to 3kW)

- Plug-in and programmable control terminals

- 6 digital inputs, 1 multifunction input

- 1 digital output, 1 multifunction output

- 1 relay output (changeover contact)

Software features

Main software features

- Positioning function via field bus (Motion Control compatible to CiA DS402)

- Rotary table control

- Master/slave function with electronic gear

- Power failure regulation

- Function for lift, crane and winch applications

- Spindle control

- Traverse function for winders

- Programmable reference value channel

- Programmable start and stop characteristics

- Motor potentiometer

- Programmable S curve

- 4 data sets

- Auto startup and commissioning

- Auto reset after failure

- Auto start after power failure

- PI controller

- Volume flow control

- Jerkfree torque/speed changeover

- Mechanical brake control free of friction

- Index control

- Intelligent current limits

- Comprehensive monitoring and protection capabilities

- High-speed control

- 3 different brake management functions

Power range

• ANG210: 0.25 - 9.2 kW / single or three-phase 200 - 240V / 50 - 60 Hz (± 10%)

• ANG410: 0.25 - 400 kW / three phase 360 - 480V / 50 - 60 Hz (±10%)

Parallel connection up to 1200 kW

• ANG510: 160 - 400 kW / three phase 525V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

• ANG610: 160 - 400 kW / three phase 690V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

• ANG410: 0.25 - 400 kW / three phase 360 - 480V / 50 - 60 Hz (±10%)

Parallel connection up to 1200 kW

• ANG510: 160 - 400 kW / three phase 525V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

• ANG610: 160 - 400 kW / three phase 690V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

Mounting options

• Cabinet mounting for all sizes

• Optional feed-through mounting

• Optional DIN rail mounting frame

size 1

• Optional Cold Plate (sizes 1 to 5)

• Optional Liquid Cooling (sizes 5 to 8)

• Optional feed-through mounting

• Optional DIN rail mounting frame

size 1

• Optional Cold Plate (sizes 1 to 5)

• Optional Liquid Cooling (sizes 5 to 8)

Motor options

Motor Control (open loop or optional closed loop):

• Asynchronous AC motors

• Permanent magnet synchronous (brushless) motors

• Asynchronous AC motors

• Permanent magnet synchronous (brushless) motors

Types & Powers

Power size types in kW* (ANG210)

| ANG 210- 01 | 1 | 0.25 |

|---|---|---|

| ANG 210- 03 | 1 | 0.37 |

| ANG 210- 05 | 1 | 0.55 |

| ANG 210- 07 | 1 | 0.75 |

| ANG 210- 09 | 1 | 1.1 |

| ANG 210- 11 | 2 | 1.5 |

| ANG 210- 13 | 2 | 2.2 |

| ANG 210- 15 | 2 | 3 |

| ANG 210- 18 | 3 | 4 |

| ANG 210- 19 | 3 | 5.5 |

| ANG 210- 21 | 4 | 7.5 |

| ANG 210- 22 | 4 | 9.2 |

Power size types in kW* (ANG410)

| ANG 410- 01 | 1 | 0.25 |

|---|---|---|

| ANG 410- 03 | 1 | 0.37 |

| ANG 410- 05 | 1 | 0.55 |

| ANG 410- 07 | 1 | 0.75 |

| ANG 410- 09 | 1 | 1.1 |

| ANG 410- 11 | 1 | 1.5 |

| ANG 410- 12 | 2 | 1.85 |

| ANG 410- 13 | 2 | 2.2 |

| ANG 410- 15 | 2 | 3 |

| ANG 410- 18 | 2 | 4 |

| ANG 410- 19 | 3 | 5.5 |

| ANG 410- 21 | 3 | 7.5 |

| ANG 410- 22 | 3 | 9.2 |

| ANG 410- 23 | 4 | 11 |

| ANG 410- 25 | 4 | 15 |

| ANG 410- 27 | 5 | 18.5 |

| ANG 410- 29 | 5 | 22 |

| ANG 410- 31 | 5 | 30 |

| ANG 410- 33 | 6 | 37 |

| ANG 410- 35 | 6 | 45 |

| ANG 410- 37 | 6 | 55 |

| ANG 410- 39 | 6 | 65 |

| ANG 410- 43 | 7 | 75 |

| ANG 410- 45 | 7 | 90 |

| ANG 410- 47 | 7 | 110 |

| ANG 410- 49 | 7 | 132 |

| ANG 410- 51 | 8 | 160 |

| ANG 410- 53 | 8 | 200 |

| ANG 410- 55 | 8 | 250 |

| ANG 410- 57 | 8 | 315 |

| ANG 410- 59 | 8 | 355 |

| ANG 410- 61 | 8 | 400 |

Power size types in kW* (ANG510)

| ANG 510- 51 | 8 | 160 |

|---|---|---|

| ANG 510- 53 | 8 | 200 |

| ANG 510- 55 | 8 | 250 |

| ANG 510- 57 | 8 | 315 |

| ANG 510- 59 | 8 | 355 |

| ANG 510- 61 | 8 | 400 |

Power size types in kW* (ANG610)

| ANG 610- 51 | 8 | 160 |

|---|---|---|

| ANG 610- 53 | 8 | 200 |

| ANG 610- 55 | 8 | 250 |

| ANG 610- 57 | 8 | 315 |

| ANG 610- 59 | 8 | 355 |

| ANG 610- 61 | 8 | 400 |

Products and solutions request